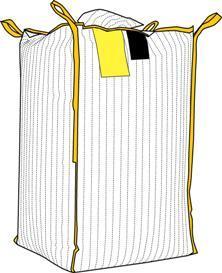

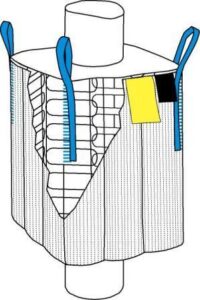

Accons Type B FIBC are particularly suitable for materials that can cause electrostatic charge during handling.

Type B is used in environments where there may be a risk of explosions.

These FIBC are made with anti-static additive in plastic and in the coating if the fabric is coated. In the table below you can see the level of type-B bag can be used for.

FIBC made of non-conductive material having a breakdown voltage no higher than 6 kV. This reliably prevents ignition of combustible dust while the explosive gas atmosphere can still be ignited.

FIBC Antistatic Type-A

Antistatic Type-A bags are our standard FIBC where no action has been taken.

FIBC made of non-conductive material without measures against electrostatic charging. Since no electrically conductive material woven into the fabric is ground and drain hardly possible.

Explosive atmospheres of gases as well as the explosive atmosphere of dust can ignite.

A Type A Big Bag should not be used when handling combustible dusts. If a FIBC is containing such material and must be used in hazardous areas, this can only be done in zones 2 or 22.